Business

Tamturbo’s Touch-Free™ technology is a 100 percent oil-free compressor technology that offers a truly ecological and sustainable compressed air solution for industrial production processes, with significantly lower life cycle costs than the traditional technology. In this way, both the environment and customers benefit.

The comprehensive compressed air compressor product family is complemented by a selection of related products and services that bring ease and reliability to the customer in the production and use of compressed air. Tamturbo’s versatile services, from mobile compressor rooms built in containers to round-the-clock remotely monitored control systems for compressors in a multi-machine environment, ensure that partners and customers can trust that the production of critical compressed air for production is guaranteed. It is also possible to implement Tamturbo’s technology as an Air-as-a-Service service, whereby customers only pay for the compressed air they use. The Air-as-a-Service contract can be based on either the compressed air used or a fixed monthly fee.

The prevailing trend in industry does not tie up capital in machines and equipment, but the necessary things are acquired through service contracts. The Air-as-a-Service business model gives Tamturbo the opportunity to change the global compressor market also at the level of the business model.

Tamturbo’s products are suitable for use in all industrial compressed air needs, and the market is not limited to customer applications requiring oil-free air. Some of the Company’s customers operate in the so-called traditional industries and for them the oil-freeness is not an intrinsic value itself. But the life cycle cost of compressed air becomes more significant in decision-making which is, according to the Company’s understanding, with Tamturbo’s technology significantly lower than that of oil-lubricated screw compressors.

However, the key customer segments of Tamturbo’s products are companies that need and want oil-free compressed air for their production without the large costs of filtering and air cleaning. Such industries include, for example, the food and beverage industry, the paper and pulp industry, the electronics industry, the automotive industry, the textile and glass industry, the chemical industry, the pharmaceutical and cosmetics industry, and the manufacturing industry, all of which use significant amounts of compressed air in their processes and for all of which the purity of the compressed air is important in terms of the quality of their own production of paramount importance.

The customer’s compressed air usage needs and requirements vary according to the variation in production. In order to be able to meet the customer requirements of the industrial medium pressure range, compressors are needed for different pressure ranges and different compressed air output rates. Tamturbo’s product family consists of compressors in two different pressure ranges, covering the industrial average pressure range of 3–9 bar.

Tamturbo has a global sales and partners network through which the Company’s technology is sold and marketed around the world. Tamturbo sells its products directly to its end customers in Finland and to large global key customers, through which sales can be expanded throughout the customer organization worldwide. A global sales, distribution and customer support network can be built most efficiently with the help of various sales partners. In accordance with Tamturbo’s strategy, the sales network utilizes a multi-channel strategy, where Tamturbo-branded products are sold through its own direct sales and distributor channel. The company does not operate in Russia.

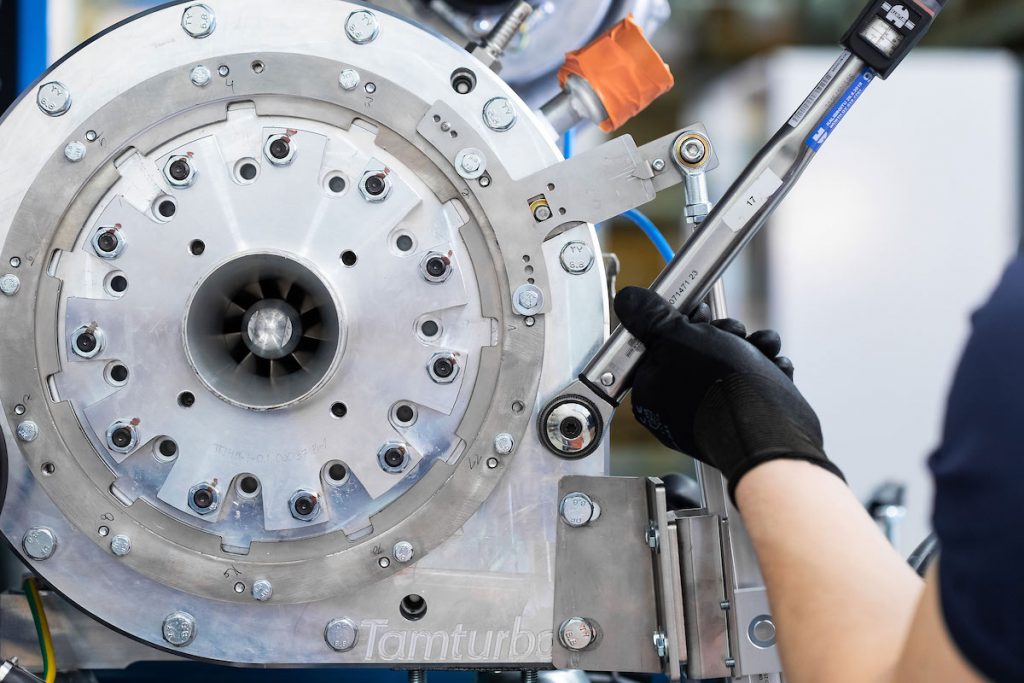

Tamturbo assembles part of its products in its rented production facilities in Ylöjärvi and partly buys the assembly from a contract assembly partner operating in the same facilities. The company buys all parts from different subcontractors and assembly and testing takes place at the company’s factory. The current annual production capacity of the production is about 25 compressors, and it can be expanded to hundreds of compressors at the current factory, incl. capacity of the contractual partner. The company’s management and quality system is ISO 9001 certified.